The microcapsules are coated with a stealth dye, a color forming agent and a temperature controlling agent. By selecting different temperature control factors, different color interval colorants can be produced.

+86-532-55571168

+86-532-55571168 sales@zrhj-qd.com

sales@zrhj-qd.com

The temperature-sensitive microcapsule powder has an average particle diameter of 3-12 um, and is a microcapsule powder mainly composed of several formulas, and the water content is ≤3%

A. Principle of discoloration: Low temperature color development and high temperature colorless

Low temperature color development

High temperature colorless

B. Product range available: -15 ° C ~ 70 ° C.

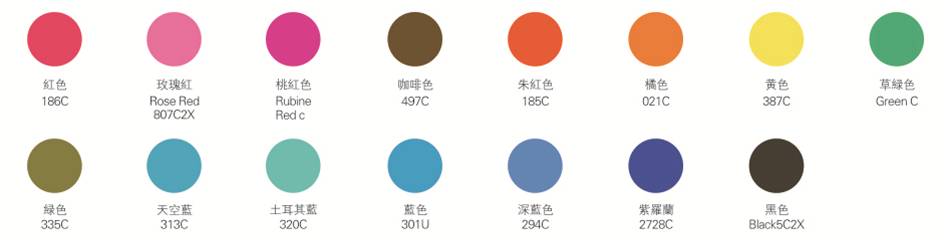

C. Basic color: 15 colors can be provided for each temperature, each color can be mixed with other color, and other color materials also can be added. (The color below is the printing color, which is based on the actual material, and the color is similar to the PANTONE color number.)

Oil based ink

Water based ink

Plastic injection

Recommended dosage: (Example: film formation 20um, plastic molding 0.2cm)

For water-based and oil-based inks and coatings 5%~30%w/w (25%)

For plastic injection and extrusion 0.1%~5%w/w(0.5%)

A. Preservation and deadline: Store in a dry and cool place. The shelf life is 2 years.

B. Test report; The company's temperature-sensitive color-changing series products have passed EN-71 and ROHS tests. It can be applied to food packaging and toy manufacturing.

C. Ink applications should avoid the use of advanced solvents such as methanol, ether, acetone, butanone to avoid penetration affecting the main components of the microcapsules.

Avoid temperatures above 240 °C when shooting applications.

work phone+86-532-55571168

Company emailsales@zrhj-qd.com

work phone+86-532-55571168

Company emailsales@zrhj-qd.com